I-PP Jumbo Bag Ukutyumza Ukuhlamba Ukomisa iPelletizing Machinery Recycling

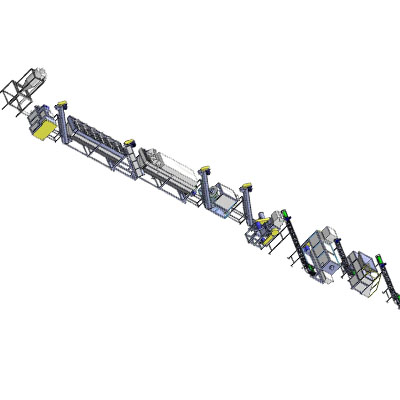

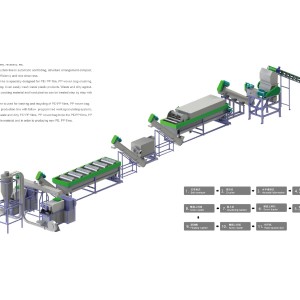

Inkunkuma yePP elukiweyo yengxowa yokutyumza umatshini wokurisayiklisha ibandakanya: isihambisi sebhanti, isityumzi (isilayisi), iwasha ebaleka ngesantya esiphezulu, iwasha edadayo, umatshini wokukhupha amanzi, umatshini wokucinezela, kunye nezinye izinto.iinkcukacha nceda ujonge le vidiyo.

iinkcukacha zokuqhubekeka:

| NO | Inkqubo | Umatshini | Inkcazo |

| 1 | Thumela ibhegi elukiweyo kumatshini wokutyumza omanzi | Umhambisi oneMetal detector(Ngokuzikhethela) | Yahlula ukungcola okunje ngentsimbi engxoweni elukiweyo, Ithumela izinto kumatshini wokutyumza omanzi. |

| 2 | Usika ibhegi ephothiweyo ibe ngamaqhekeza amancinci | Umtshini we-Crusher omanzi | Isityumzi esimanzi sisika ingxowa eyi-PP elukiweyo ibe ngamaqhekeza amancinci malunga ne-10-20mm ngobukhulu kwaye ihambe iye kwisiqwenga sesixhobo esilandelayo. |

| 3 | Thumela ibhegi elukiweyo kumatshini wokuhlamba odadayo | I-Screw Feeder | Beka ingxowa elukiweyo kwiwasha eshushu ukuyicoca |

| 4 | Ixesha lokuqala hlamba ingxowa elukiweyo | Itanki yokuvasa edadayo | Njengoko ingxowa elukiweyo ingena kwiwasha yokukhuhlana, ingxowa elukiweyo ikhuhlana enye nenye ngesantya esiphezulu isusa ungcoliseko ekunzima ukukususa. |

| 5 | Ukutya iingxowa ezilahliweyo kwiwasha yokukhuhlana | I-Screw Feeder | Beka ibhegi elukiweyo kwi-High-speed Friction Washer ukuze uyicoce |

| 6 | Yahlula ungcoliseko kwingxowa ephothiweyo yeplastiki | Umatshini wokuhlamba we-Speed High-Speed Friction | Emva kokutyumza izinto ezivela ekungeneni emlonyeni, ngesantya esiphezulu kwi-axis ye-blade flap kunye nokutshiza amanzi kumsebenzi oqhelekileyo wesiphumo esihle sokucoca. |

| 7 | Kwityeli lesibini uhlambe ingxowa elukiweyo | Itanki yokuvasa edadayo | Isetyenziselwa ukucoca iingxowa zeplastiki eziphothiweyo, ukwenza ifilimu icoceke. |

| 8 | Yomisa iplastiki ephothiweyo | Umatshini wokukhupha amanzi othe tyaba | Umatshini wokukhupha amanzi usebenzisa amandla e-centrifugal ukujikeleza ukufuma kwamanzi kwingxowa elukiweyo yeplastiki. |

| 9 | Umoya oshushu ukomisa ingxowa elukiweyo | Smachine queezer | Sukucudisa izixhobosusa ukufuma kwizinto ezicocekileyo. |

| 10 | Gcina iziqwenga ezomileyo zengxowa elukiweyo | Isisele sokugcina | Itanki yokugcina iziqwenga ezicocekileyo, ezomileyo zengxowa elukiweyo. |

| 11 | yenza iplastiki ephothiweyo ibe yigranules (Ngokuzikhethela) | Pelletizer / Extruder | Sinikezela ngee-extruders ezine-screw kunye ne-twin-screw extruders.Ngokusekwe kwiimfuno zakho, sinikezela ngenqanaba elinye kunye nenqanaba eliphindwe kabini ukuseta i-pelletizing apho iigranules zinokuthi zenziwe kusetyenziswa igranulator okanye ukusika umsesane wamanzi. |

Umatshini wokurisayikilisha weplastiki luhlobo lwezixhobo ezisetyenziselwa ukusetyenzwa ngokutsha kwenkunkuma yeplastiki kwiigranuli okanye iipeliti ezinokuthi ziphinde zisetyenziswe ekwenzeni iimveliso zeplastiki ezintsha.Umatshini usebenza ngokucofa okanye ukucola inkunkuma yeplastiki ibe ngamaqhekeza amancinci, emva koko uyinyibilikise kwaye uyikhuphe ngokufa ukwenza iipellets okanye iigranules.

Kukho iintlobo ezahlukeneyo zeplastiki zokurisayikilisha kunye noomatshini begranulating abakhoyo, kubandakanywa isikrufu esinye kunye ne-twin-screw extruders.Abanye oomatshini baquka iimpawu ezongezelelweyo ezifana nezikrini zokususa ukungcola kwinkunkuma yeplastiki okanye iinkqubo zokupholisa ukuqinisekisa ukuba iipelisi ziqiniswe ngokufanelekileyo.Umatshini wokuhlamba ibhotile ye-PET, i-PP elukiweyo yeengxowa zomgca wokuhlamba

Oomatshini beplastiki bokurisayikilisha kunye noomatshini bokwenza igranulayitha baqhele ukusetyenziswa kwimizi-mveliso eyenza isixa esikhulu senkunkuma yeplastiki, njengokupakishwa, iimoto kunye nokwakha.Ngokuphinda kusetyenziswe inkunkuma yeplastiki, aba matshini banceda ukunciphisa impembelelo yokusingqongileyo yokulahlwa kweplastiki kunye nokugcina izixhobo ngokusebenzisa izinto ebezinokulahlwa ngenye indlela.

Isixhobo sokurisayikilisha ibhetri yeLithium luhlobo lwezixhobo ezisetyenziselwa ukurisayikilisha nokubuyisela izinto ezixabisekileyo kwiibhetri ze-lithium-ion, eziqhele ukusetyenziswa kwizixhobo zombane ezifana nee-smartphones, iilaptops, kunye nezithuthi zombane.Isixhobo sisebenza ngokuqhekeza iibhetri kwiindawo zazo, njenge-cathode kunye nemathiriyeli ye-anode, isisombululo se-electrolyte, kunye neefoyile zetsimbi, kwaye emva koko zahlula kwaye zihlambulule ezi mathiriyeli ukuze zisetyenziswe kwakhona.

Kukho iintlobo ezahlukeneyo zezixhobo zokuhlaziya ibhetri ye-lithium ezikhoyo, kubandakanywa iinkqubo ze-pyrometallurgical, iinkqubo ze-hydrometallurgical, kunye neenkqubo zoomatshini.Iinkqubo zePyrometallurgical zibandakanya ukusetyenzwa kobushushu obuphezulu beebhetri ukubuyisela iintsimbi ezinje ngobhedu, nickel, kunye necobalt.Iinkqubo ze-Hydrometallurgical zisebenzisa izisombululo zekhemikhali ukunyibilikisa amacandelo ebhetri kunye nokubuyisela iintsimbi, ngelixa iinkqubo zoomatshini zibandakanya ukuqhekeza kunye nokugaya iibhetri ukwahlula izixhobo.

Isixhobo sokurisayikilisha ibhetri yeLithium sibalulekile ekunciphiseni impembelelo yokusingqongileyo yokulahlwa kwebhetri kunye nokugcina izixhobo ngokufumana kwakhona iintsimbi ezixabisekileyo kunye nezinto ezinokuthi ziphinde zisetyenziswe kwiibhetri ezintsha okanye ezinye iimveliso.

Ukongeza kwiinzuzo zokusingqongileyo kunye nokugcinwa kwezibonelelo, izixhobo zokuphinda zisetyenziswe ibhetri ye-lithium nazo zineenzuzo zoqoqosho.Ukufumana kwakhona isinyithi esixabisekileyo kunye nezinto ezivela kwiibhetri ezisetyenzisiweyo kunokunciphisa iindleko zokuvelisa iibhetri ezintsha, kunye nokudala imithombo emitsha yengeniso kwiinkampani ezibandakanyekayo kwinkqubo yokubuyisela kwakhona.

Ngaphaya koko, ukwanda kwemfuno yezithuthi zombane kunye nezinye izixhobo zombane kuqhuba imfuneko yoshishino olusebenzayo noluzinzileyo lokurisayikilisha kweebhetri.Isixhobo sokurisayikilisha ibhetri yeLithium singanceda ukuhlangabezana nale mfuno ngokubonelela ngendlela ethembekileyo nengabiziyo yokufumana kwakhona imathiriyeli exabisekileyo kwiibhetri ezisetyenzisiweyo.

Nangona kunjalo, kubalulekile ukuqaphela ukuba ukwenziwa kwakhona kwebhetri ye-lithium kuseyishishini elitsha noko, kwaye kukho imiceli mngeni ekufuneka yoyiswe malunga nokuphuhlisa iinkqubo zokurisayikilisha ezisebenzayo nezingabizi kakhulu.Ukongeza, ukuphathwa ngokufanelekileyo kunye nokulahlwa kwenkunkuma yebhetri kubalulekile ukuphepha iingozi zendalo kunye nempilo.Ngoko ke, imimiselo efanelekileyo kunye namanyathelo okhuseleko kufuneka abekhona ukuze kuqinisekiswe ukuphathwa ngokufanelekileyo kunye nokuhlaziywa kweebhetri ze-lithium.