Izigaba ezibini zeplastiki Ifilim kunye neentsinga kunye neengxowa Umatshini wePelletizing

Ividiyo yeMveliso:

Ukwenziwa kweMifanekiso yeMathiriyeli:

NONE

I-HDPE, i-LDPE, i-LLDPE, i-PP, efana neefilimu, iibhegi, iiflakes, iiroli zefilimu, ifilimu eyolulayo, ifilimu eshwabeneyo, ifilimu enamaleko amaninzi, ibhegi yeT-shirt esikiweyo.

I-PE enogwebu, i-EPS kunye ne-XPS: iiroli, ibhegi, iphepha, isikhongozeli sokutya, umnatha weziqhamo, ikhava

Umbhalo: I-PP fiber, i-raffia, isilika, intambo, ibhegi elukiweyo, ibhegi yejumbo

Iimbonakalo:

Le nkqubo yokudibanisa i-pelletizing edibeneyo inceda imathiriyeli ehlaziyiweyo ngaphandle kokusika kwangaphambili

Ukudibanisa ukufumana ukuxhotyiswa ngeevalvu zokusika, ezisetyenziselwa ukulawula isantya sokutyisa izinto

Inkqubo yokufunxa yokukhupha amanzi okanye igesi kubungakanani obukhulu

Isihluzi esigqwesileyo se-hydraulic screen kunye noxinzelelo oluzinzileyo lokungayeki, ukungavuzi

Ukonga amandla ngemveliso ephezulu (0.28kwh/kg)

Inkqubo yokusebenza ngokubanzi:

1.Ibhanti yokudlulisa imathiriyeli kwi-compactor eqhekezayo.

2.Inkqubo yokulawula i-interlock phakathi kwebhanti yokuhambisa kunye nokuqhawula i-compactor iqinisekisa ukutya okulinganayo ngaphandle kwe-compactor enyibilikisiweyo.

3.Ezantsi kwe shredding compactor, kukho ibhodi enye yokusika.ngamandla ase-centrifugal, imathiriyeli esetyenzisiweyo iyasikwa kwangaphambili ngabasiki abajikelezayo kunye nabasiki abamileyo.

4.Emva koko, imathiriyeli ingena kwisikrufu sokukhupha igesi ukusuka kwicala le-compactor.

5.Ngokufudumeza isijivu, iplastiki iba yimpahla ye-semi-plastification.

6.Kwaye emva koko, imathiriyeli ye-semi-plastiki isikwe kwiipellets.

IParameter yoBugcisa engundoqo:

| Umzekelo | ML75 | ML85/SJ90 | ML100/SJ120 | ML130/SJ140 | ML160/SJ180 | ML180/SJ200 |

| Idayamitha yesikruru(mm) | 75 | Inqanaba lokuqala 85Inqanaba lesibini lama-90 | Inqanaba lokuqala 100Inqanaba lesibini le-120 | Inqanaba lokuqala:130Inqanaba lesibini:140 | Inqanaba lokuqala:160Inqanaba lesibini:180 | Inqanaba lokuqala:180Inqanaba lesibini:200 |

| L/D | Inqanaba lokuqala: 26 ukuya 37Inqanaba lesibini:10 ukuya 15 | |||||

| Imveliso(kg/h) | 100-150 | 150-250 | 250- 350 | 450-550 | 600-800 | 1000 |

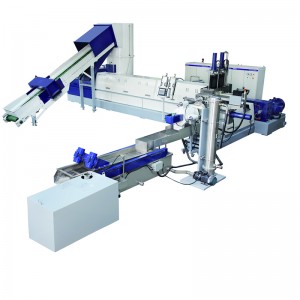

Imifanekiso yoomatshini:

Isikrufu esinye

Iqonga eliphindwe kabini lokurisayikilisha i-extruder

Iinkcukacha zajikelele:

| Igama lomzekelo | ML |

| imveliso | Iipeliti zeplastiki/iigranuli/iiresi/iplastiki imathiriyeli ekrwada |

| Amalungu omatshini | Ukuhambisa ibhanti, i-cutter compactor, i-extruder engundoqo, iyunithi ye-pelletizing, inkqubo yokupholisa, isisele, ikhabhathi |

| Imathiriyeli yokurisayikilisha | Ifilimu yePP / PE / LDPE / HDPE, isikhwama, ifayibha |

| Uluhlu lwezakhono | 100kg/h ukuya 1200kg/h |

| Indlela yokutya | Umthumeli, inkqubo yokuqhuba |

| Screw diameter | 75mm ukuya 200mm |

| Isikrufu L/D | 26 ukuya ku33 |

| Screw imathiriyeli ekrwada | 38CrMoAl okanye i-bimetallic |

| ukukhupha umoya | Ukukhutshwa kwegesi yendalo, ukukhupha i-vacuum degassing |

| Ukusika uhlobo | Indlela ye-pelletizing ethe nkqo, tsala i-strip pelletizing |

| Uhlobo lokupholisa | Amanzi aphole, umoya upholile |

| I-Voltage | Customized |

| Izixhobo ozikhethelayo | Isibonisi sesinyithi, inkqubo yokupholisa amanzi, isisele sokutyisa, inkqubo yokungcangcazela |

| Ixesha lokuzisa | Iintsuku ezingama-40 ukuya kwezingama-60 |

| Ixesha lewaranti | Iinyanga ezili-13 |

| Iinkxaso zobugcisa | Uyilo lomatshini, uyilo lofakelo, inkonzo yobunjineli phesheya kolwandle |

| Isatifikethi | CE/ SGS/TUV/CO |

Kutheni ukhetha thina?

I-A.PURUI inomvelisi oyingcali ukususela ngo-2006. sinesebe lethu loyilo lobugcisa.I-extruder nganye iyilwe ngokwezinto ezibonakalayo.

B.Ukugcina amandla ngemveliso ephezulu

C.Ixesha loqinisekiso loBulunga ziinyanga ezili-12 ukusukela kumhla weBill of Lading.

D. Ixesha lokuhambisa: Iintsuku zokusebenza ezingama-40 ukuya kwiintsuku ezingama-60

Iphakheji eceliweyo ye-E.Ship

Ufakelo lwe-F.Machine lukhona.Kuthatha malunga neentsuku ezi-5 ukuya kwezi-7 ngokugqiba ixesha elinye lofakelo.Iinjineli ezabelweyo zilawula uqeqesho lomsebenzisi womatshini, ukusebenza komatshini kunye nekhomishini.

Intshayelelo yeNkampani:

I-Chengdu PuRui Polymer Engineering Co. Ltd ngomnye wabavelisi abakhokelayo koomatshini bokurisayikilisha beplastiki, i-extruder, igranulator yeplastiki kunye nezixhobo ezincedisayo ezinxulumeneyo e-China.Iingenelo ezizodwa zenkqubo yethu yeplastiki yepelletizing kuyilo lwezikrufu, imveliso ephezulu, ukukhupha igesi elungileyo kunye nesiphumo esihle sokucoca.Umgca wethu wokuhlamba iiplastiki ezifana ne-crusher enokunyamezeleka kunye ne-cutter ebukhali, iiyunithi zokuhlamba, ukwahlula okanye umatshini wokuhlela, inkqubo yokomisa, kunye nenkqubo yokupakisha ikumgangatho ovakalayo.

Umatshini wokurisayikilisha weplastiki luhlobo lwezixhobo ezisetyenziselwa ukusetyenzwa ngokutsha kwenkunkuma yeplastiki kwiigranuli okanye iipeliti ezinokuthi ziphinde zisetyenziswe ekwenzeni iimveliso zeplastiki ezintsha.Umatshini usebenza ngokucofa okanye ukucola inkunkuma yeplastiki ibe ngamaqhekeza amancinci, emva koko uyinyibilikise kwaye uyikhuphe ngokufa ukwenza iipellets okanye iigranules.

Kukho iintlobo ezahlukeneyo zeplastiki zokurisayikilisha kunye noomatshini begranulating abakhoyo, kubandakanywa isikrufu esinye kunye ne-twin-screw extruders.Abanye oomatshini baquka iimpawu ezongezelelweyo ezifana nezikrini zokususa ukungcola kwinkunkuma yeplastiki okanye iinkqubo zokupholisa ukuqinisekisa ukuba iipelisi ziqiniswe ngokufanelekileyo.Umatshini wokuhlamba ibhotile ye-PET, i-PP elukiweyo yeengxowa zomgca wokuhlamba

Oomatshini beplastiki bokurisayikilisha kunye noomatshini bokwenza igranulayitha baqhele ukusetyenziswa kwimizi-mveliso eyenza isixa esikhulu senkunkuma yeplastiki, njengokupakishwa, iimoto kunye nokwakha.Ngokuphinda kusetyenziswe inkunkuma yeplastiki, aba matshini banceda ukunciphisa impembelelo yokusingqongileyo yokulahlwa kweplastiki kunye nokugcina izixhobo ngokusebenzisa izinto ebezinokulahlwa ngenye indlela.

Isixhobo sokurisayikilisha ibhetri yeLithium luhlobo lwezixhobo ezisetyenziselwa ukurisayikilisha nokubuyisela izinto ezixabisekileyo kwiibhetri ze-lithium-ion, eziqhele ukusetyenziswa kwizixhobo zombane ezifana nee-smartphones, iilaptops, kunye nezithuthi zombane.Isixhobo sisebenza ngokuqhekeza iibhetri kwiindawo zazo, njenge-cathode kunye nemathiriyeli ye-anode, isisombululo se-electrolyte, kunye neefoyile zetsimbi, kwaye emva koko zahlula kwaye zihlambulule ezi mathiriyeli ukuze zisetyenziswe kwakhona.

Kukho iintlobo ezahlukeneyo zezixhobo zokuhlaziya ibhetri ye-lithium ezikhoyo, kubandakanywa iinkqubo ze-pyrometallurgical, iinkqubo ze-hydrometallurgical, kunye neenkqubo zoomatshini.Iinkqubo zePyrometallurgical zibandakanya ukusetyenzwa kobushushu obuphezulu beebhetri ukubuyisela iintsimbi ezinje ngobhedu, nickel, kunye necobalt.Iinkqubo ze-Hydrometallurgical zisebenzisa izisombululo zekhemikhali ukunyibilikisa amacandelo ebhetri kunye nokubuyisela iintsimbi, ngelixa iinkqubo zoomatshini zibandakanya ukuqhekeza kunye nokugaya iibhetri ukwahlula izixhobo.

Isixhobo sokurisayikilisha ibhetri yeLithium sibalulekile ekunciphiseni impembelelo yokusingqongileyo yokulahlwa kwebhetri kunye nokugcina izixhobo ngokufumana kwakhona iintsimbi ezixabisekileyo kunye nezinto ezinokuthi ziphinde zisetyenziswe kwiibhetri ezintsha okanye ezinye iimveliso.

Ukongeza kwiinzuzo zokusingqongileyo kunye nokugcinwa kwezibonelelo, izixhobo zokuphinda zisetyenziswe ibhetri ye-lithium nazo zineenzuzo zoqoqosho.Ukufumana kwakhona isinyithi esixabisekileyo kunye nezinto ezivela kwiibhetri ezisetyenzisiweyo kunokunciphisa iindleko zokuvelisa iibhetri ezintsha, kunye nokudala imithombo emitsha yengeniso kwiinkampani ezibandakanyekayo kwinkqubo yokubuyisela kwakhona.

Ngaphaya koko, ukwanda kwemfuno yezithuthi zombane kunye nezinye izixhobo zombane kuqhuba imfuneko yoshishino olusebenzayo noluzinzileyo lokurisayikilisha kweebhetri.Isixhobo sokurisayikilisha ibhetri yeLithium singanceda ukuhlangabezana nale mfuno ngokubonelela ngendlela ethembekileyo nengabiziyo yokufumana kwakhona imathiriyeli exabisekileyo kwiibhetri ezisetyenzisiweyo.

Nangona kunjalo, kubalulekile ukuqaphela ukuba ukwenziwa kwakhona kwebhetri ye-lithium kuseyishishini elitsha noko, kwaye kukho imiceli mngeni ekufuneka yoyiswe malunga nokuphuhlisa iinkqubo zokurisayikilisha ezisebenzayo nezingabizi kakhulu.Ukongeza, ukuphathwa ngokufanelekileyo kunye nokulahlwa kwenkunkuma yebhetri kubalulekile ukuphepha iingozi zendalo kunye nempilo.Ngoko ke, imimiselo efanelekileyo kunye namanyathelo okhuseleko kufuneka abekhona ukuze kuqinisekiswe ukuphathwa ngokufanelekileyo kunye nokuhlaziywa kweebhetri ze-lithium.