Ukuthengiswa Okushushu kwiNkonzo yePlastiki yokuRisayikilishwa Umatshini wokuhlamba

Intshayelelo yenkqubo

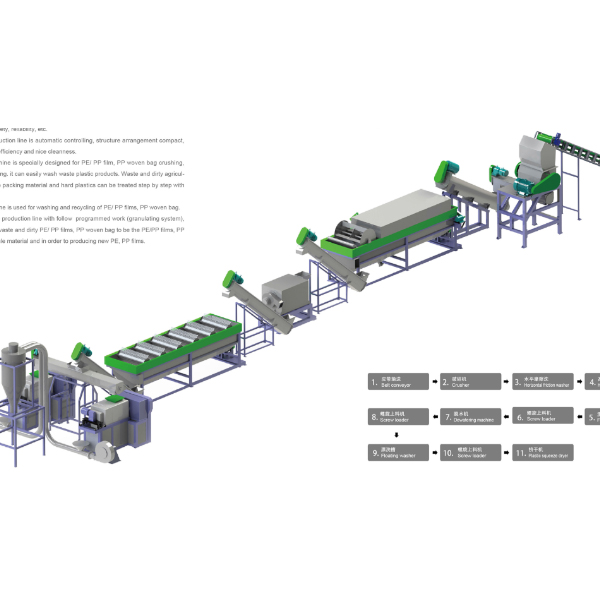

Lo mgca wemveliso uhlaziya ifilimu yenkunkuma yezolimo (ifilimu yezolimo/ifilimu yegreenhouse/ifilimu yecuba, njl. njl.).Okwangoku, ifilimu yenkunkuma yezolimo icutshungulwa kwiindawo ezahlukeneyo zelizwe ukuze isetyenziselwe indawo esembindini kunye nokuphinda isetyenziswe, kwaye iqondo lokuzenzekelayo kwezixhobo liye landa.U-PULIER uye wabandakanyeka ekwenzeni inkunkuma yefilimu yezolimo kunye nezixhobo zokusebenza iminyaka emininzi, kwaye izixhobo zihlaziywa rhoqo, ziphuculwe kwaye ziphuculwe kwaye zisombulule iingxaki ezininzi kwishishini ngokusebenzisa iteknoloji yethu.Emva kokuba ifilimu yenkunkuma iqokelelwe, iqhutywe ngaphambili kwaye inqunyulwe okanye ihlulwe ukuze iguqule imiqulu emikhulu yefilimu yenkunkuma ibe ngamaqhekeza amancinci kwaye ayifake kumatshini wokususa isanti ukwenzela unyango lokususa isanti.Umxholo wentlenga ogqithisileyo uya kunciphisa ubomi benkonzo ye-crusher kwaye uchaphazele umphumo wokucoca.Emva kokususwa kwesanti, ifilimu ingena kwi-crusher yonyango olucolileyo.Amanzi ongezwa ngokutyumza, onokudlala indima yokucoca kwangaphambili.I-friction washer ixhotyiswe ezantsi kwe-crusher, enokuthi ishukumise intlenga kunye namanzi angcolileyo kwizinto eziphathekayo.Ifilimu eyomileyo ingena kwiwasha eyomeleleyo yokucoca i-friction.Eli candelo lizaliswe ngamanzi okucoca i-friction.Inkampani yethu iyila ngokukodwa lo matshini wokususwa kwesanti kunye nokucoca ifilimu ye-mulch.Intlenga yokucoca ingaphezulu kwama-99%.Ifilimu ecociweyo ingena kwiwasha edadayo kwaye emva koko igrunjwe kwisixhobo esomileyo sokuphelelwa ngamanzi emzimbeni.Okulandelayo kunokudityaniswa kumgca wegranulating ukwenza iigranules.

ukuqhubela phambili:

1. ibhanti lokuhambisa 2. isityuli 3. isikrufu sokulayisha 4. iwasha exwebileyo ethe tyaba 5. iwasha yefriction yesantya esiphezulu 6. isikrufu sokulayisha 7. itanki edadayo emibini.

8. iwasha exwebileyo ethe tye 9. isikrufu sokulayisha 10. itanki yamanzi 11. i-horizontal spiral 12. isikrufu sokulayisha 13. umatshini wokukhahlela

ividiyo nceda ujonge njengamakhonkco angezantsi:

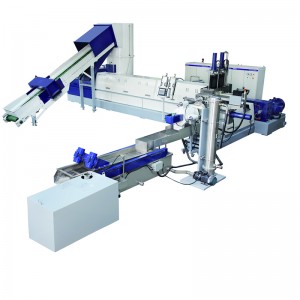

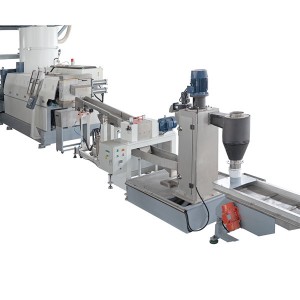

Umatshini wokurisayikilisha weplastiki luhlobo lwezixhobo ezisetyenziselwa ukusetyenzwa ngokutsha kwenkunkuma yeplastiki kwiigranuli okanye iipeliti ezinokuthi ziphinde zisetyenziswe ekwenzeni iimveliso zeplastiki ezintsha.Umatshini usebenza ngokucofa okanye ukucola inkunkuma yeplastiki ibe ngamaqhekeza amancinci, emva koko uyinyibilikise kwaye uyikhuphe ngokufa ukwenza iipellets okanye iigranules.

Kukho iintlobo ezahlukeneyo zeplastiki zokurisayikilisha kunye noomatshini begranulating abakhoyo, kubandakanywa isikrufu esinye kunye ne-twin-screw extruders.Abanye oomatshini baquka iimpawu ezongezelelweyo ezifana nezikrini zokususa ukungcola kwinkunkuma yeplastiki okanye iinkqubo zokupholisa ukuqinisekisa ukuba iipelisi ziqiniswe ngokufanelekileyo.Umatshini wokuhlamba ibhotile ye-PET, i-PP elukiweyo yeengxowa zomgca wokuhlamba

Oomatshini beplastiki bokurisayikilisha kunye noomatshini bokwenza igranulayitha baqhele ukusetyenziswa kwimizi-mveliso eyenza isixa esikhulu senkunkuma yeplastiki, njengokupakishwa, iimoto kunye nokwakha.Ngokuphinda kusetyenziswe inkunkuma yeplastiki, aba matshini banceda ukunciphisa impembelelo yokusingqongileyo yokulahlwa kweplastiki kunye nokugcina izixhobo ngokusebenzisa izinto ebezinokulahlwa ngenye indlela.

Isixhobo sokurisayikilisha ibhetri yeLithium luhlobo lwezixhobo ezisetyenziselwa ukurisayikilisha nokubuyisela izinto ezixabisekileyo kwiibhetri ze-lithium-ion, eziqhele ukusetyenziswa kwizixhobo zombane ezifana nee-smartphones, iilaptops, kunye nezithuthi zombane.Isixhobo sisebenza ngokuqhekeza iibhetri kwiindawo zazo, njenge-cathode kunye nemathiriyeli ye-anode, isisombululo se-electrolyte, kunye neefoyile zetsimbi, kwaye emva koko zahlula kwaye zihlambulule ezi mathiriyeli ukuze zisetyenziswe kwakhona.

Kukho iintlobo ezahlukeneyo zezixhobo zokuhlaziya ibhetri ye-lithium ezikhoyo, kubandakanywa iinkqubo ze-pyrometallurgical, iinkqubo ze-hydrometallurgical, kunye neenkqubo zoomatshini.Iinkqubo zePyrometallurgical zibandakanya ukusetyenzwa kobushushu obuphezulu beebhetri ukubuyisela iintsimbi ezinje ngobhedu, nickel, kunye necobalt.Iinkqubo ze-Hydrometallurgical zisebenzisa izisombululo zekhemikhali ukunyibilikisa amacandelo ebhetri kunye nokubuyisela iintsimbi, ngelixa iinkqubo zoomatshini zibandakanya ukuqhekeza kunye nokugaya iibhetri ukwahlula izixhobo.

Isixhobo sokurisayikilisha ibhetri yeLithium sibalulekile ekunciphiseni impembelelo yokusingqongileyo yokulahlwa kwebhetri kunye nokugcina izixhobo ngokufumana kwakhona iintsimbi ezixabisekileyo kunye nezinto ezinokuthi ziphinde zisetyenziswe kwiibhetri ezintsha okanye ezinye iimveliso.

Ukongeza kwiinzuzo zokusingqongileyo kunye nokugcinwa kwezibonelelo, izixhobo zokuphinda zisetyenziswe ibhetri ye-lithium nazo zineenzuzo zoqoqosho.Ukufumana kwakhona isinyithi esixabisekileyo kunye nezinto ezivela kwiibhetri ezisetyenzisiweyo kunokunciphisa iindleko zokuvelisa iibhetri ezintsha, kunye nokudala imithombo emitsha yengeniso kwiinkampani ezibandakanyekayo kwinkqubo yokubuyisela kwakhona.

Ngaphaya koko, ukwanda kwemfuno yezithuthi zombane kunye nezinye izixhobo zombane kuqhuba imfuneko yoshishino olusebenzayo noluzinzileyo lokurisayikilisha kweebhetri.Isixhobo sokurisayikilisha ibhetri yeLithium singanceda ukuhlangabezana nale mfuno ngokubonelela ngendlela ethembekileyo nengabiziyo yokufumana kwakhona imathiriyeli exabisekileyo kwiibhetri ezisetyenzisiweyo.

Nangona kunjalo, kubalulekile ukuqaphela ukuba ukwenziwa kwakhona kwebhetri ye-lithium kuseyishishini elitsha noko, kwaye kukho imiceli mngeni ekufuneka yoyiswe malunga nokuphuhlisa iinkqubo zokurisayikilisha ezisebenzayo nezingabizi kakhulu.Ukongeza, ukuphathwa ngokufanelekileyo kunye nokulahlwa kwenkunkuma yebhetri kubalulekile ukuphepha iingozi zendalo kunye nempilo.Ngoko ke, imimiselo efanelekileyo kunye namanyathelo okhuseleko kufuneka abekhona ukuze kuqinisekiswe ukuphathwa ngokufanelekileyo kunye nokuhlaziywa kweebhetri ze-lithium.