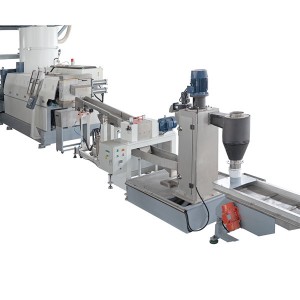

Umatshini we-pelletizing we-SJ we-PP PE iiplastiki eziqinileyo kunye neeplastiki ezikhanyiweyo

Ividiyo:

Iinkcukacha zajikelele:

Umatshini we-pelletizing we-SJ wenzelwe iiplastiki eziqinileyo zokurisayikilisha, ezifana ne-PE, PP, i-PS, i-ABS, i-PC, i-PA6 njl kunye neebhotile zeshampu, njl njl.

Isicelo:

l Icolile okanye iphinde iphinde i-PE, PP, PS, ABS, PC, PA6

l Iifilimu zePP kunye nePE ezicudiweyo zicudiwe.

Iimbonakalo:

1.Amaxesha amabini ukuhluza kuya kuqinisekisa umgangatho weepellets.Ubungakanani bemesh yokucoca inqanaba lokuqala linokusebenzisa i-60mesh.Inqanaba lesibini lokucoca i-mesh liya kuba yi-80-100mesh.

2.Great vacuum degassing inkqubo.Sisebenzisa ipompo yokunkcenkceshela i-vacuum kumgca we-pelletizing.Isicatshulwa segesi esiphelileyo esivela kwi-extruder kwaye singena kwi-cylinder yamanzi yokucoca.

I-3.Uyilo lwe-screw lukhethekileyo kwizinto ezithile.

I-4.Izifudumezi esazisebenzisayo kwi-barrel zingcono kwaye zithembeke e-China kunye nexesha elide lenkonzo.

5.Indlela yePelletizing iyakhethwa.I-pelletizing yokunkcenkceshela ifanelekile kwiifilimu ze-PP kunye ne-PE, ngelixa i-strand pelletizing ingasetyenziselwa kwi-PP PE kunye ne-PC kunye ne-ABS kunye ne-PA.Kwakhona i-pelletizing engaphantsi kwamanzi iya kuba yinto yonke.Yonke indlela ye-pelletizing iya kuba lula ukuyigcina kunye nexesha elide lenkonzo.

6.Iimpawu zeemoto ezilungileyo kunye nebhokisi yegiya yetorque ephezulu.Sisebenzisa ezona moto zibalaseleyo zaseTshayina, iDazhong, kunye ne-WEG enesatifikethi se-UL, iimotor ze-ABB, kunye neemotor ze-Siemens ngokuzithandela.Amalungu ombane asebenzisa uphawu lwamazwe ngamazwe lwe-Schneider okanye i-Siemens.Ulawulo lobushushu OMRON.Ulawulo lwe-Siemens PLC luyafumaneka.Indlela efanelekileyo yokukhusela umbane kumatshini.

7.Uyilo oluhle lokhuseleko kunye nokusetyenziswa kwiplanti.Sinolawulo olungqongqo lwekhwalithi.

Besikule ntsimi yeplastiki ye-pelletiizng iminyaka engaphezu kwe-16 sithumela kumazwe angaphezu kwama-80 kwihlabathi jikelele.Ngamava amaninzi kunye nabasebenzi betekhnoloji ukusombulula yakhoumatshini wokurisayikilisha weplastiki.

Umatshini wokurisayikilisha weplastiki luhlobo lwezixhobo ezisetyenziselwa ukusetyenzwa ngokutsha kwenkunkuma yeplastiki kwiigranuli okanye iipeliti ezinokuthi ziphinde zisetyenziswe ekwenzeni iimveliso zeplastiki ezintsha.Umatshini usebenza ngokucofa okanye ukucola inkunkuma yeplastiki ibe ngamaqhekeza amancinci, emva koko uyinyibilikise kwaye uyikhuphe ngokufa ukwenza iipellets okanye iigranules.

Kukho iintlobo ezahlukeneyo zeplastiki zokurisayikilisha kunye noomatshini begranulating abakhoyo, kubandakanywa isikrufu esinye kunye ne-twin-screw extruders.Abanye oomatshini baquka iimpawu ezongezelelweyo ezifana nezikrini zokususa ukungcola kwinkunkuma yeplastiki okanye iinkqubo zokupholisa ukuqinisekisa ukuba iipelisi ziqiniswe ngokufanelekileyo.Umatshini wokuhlamba ibhotile ye-PET, i-PP elukiweyo yeengxowa zomgca wokuhlamba

Oomatshini beplastiki bokurisayikilisha kunye noomatshini bokwenza igranulayitha baqhele ukusetyenziswa kwimizi-mveliso eyenza isixa esikhulu senkunkuma yeplastiki, njengokupakishwa, iimoto kunye nokwakha.Ngokuphinda kusetyenziswe inkunkuma yeplastiki, aba matshini banceda ukunciphisa impembelelo yokusingqongileyo yokulahlwa kweplastiki kunye nokugcina izixhobo ngokusebenzisa izinto ebezinokulahlwa ngenye indlela.

Isixhobo sokurisayikilisha ibhetri yeLithium luhlobo lwezixhobo ezisetyenziselwa ukurisayikilisha nokubuyisela izinto ezixabisekileyo kwiibhetri ze-lithium-ion, eziqhele ukusetyenziswa kwizixhobo zombane ezifana nee-smartphones, iilaptops, kunye nezithuthi zombane.Isixhobo sisebenza ngokuqhekeza iibhetri kwiindawo zazo, njenge-cathode kunye nemathiriyeli ye-anode, isisombululo se-electrolyte, kunye neefoyile zetsimbi, kwaye emva koko zahlula kwaye zihlambulule ezi mathiriyeli ukuze zisetyenziswe kwakhona.

Kukho iintlobo ezahlukeneyo zezixhobo zokuhlaziya ibhetri ye-lithium ezikhoyo, kubandakanywa iinkqubo ze-pyrometallurgical, iinkqubo ze-hydrometallurgical, kunye neenkqubo zoomatshini.Iinkqubo zePyrometallurgical zibandakanya ukusetyenzwa kobushushu obuphezulu beebhetri ukubuyisela iintsimbi ezinje ngobhedu, nickel, kunye necobalt.Iinkqubo ze-Hydrometallurgical zisebenzisa izisombululo zekhemikhali ukunyibilikisa amacandelo ebhetri kunye nokubuyisela iintsimbi, ngelixa iinkqubo zoomatshini zibandakanya ukuqhekeza kunye nokugaya iibhetri ukwahlula izixhobo.

Isixhobo sokurisayikilisha ibhetri yeLithium sibalulekile ekunciphiseni impembelelo yokusingqongileyo yokulahlwa kwebhetri kunye nokugcina izixhobo ngokufumana kwakhona iintsimbi ezixabisekileyo kunye nezinto ezinokuthi ziphinde zisetyenziswe kwiibhetri ezintsha okanye ezinye iimveliso.

Ukongeza kwiinzuzo zokusingqongileyo kunye nokugcinwa kwezibonelelo, izixhobo zokuphinda zisetyenziswe ibhetri ye-lithium nazo zineenzuzo zoqoqosho.Ukufumana kwakhona isinyithi esixabisekileyo kunye nezinto ezivela kwiibhetri ezisetyenzisiweyo kunokunciphisa iindleko zokuvelisa iibhetri ezintsha, kunye nokudala imithombo emitsha yengeniso kwiinkampani ezibandakanyekayo kwinkqubo yokubuyisela kwakhona.

Ngaphaya koko, ukwanda kwemfuno yezithuthi zombane kunye nezinye izixhobo zombane kuqhuba imfuneko yoshishino olusebenzayo noluzinzileyo lokurisayikilisha kweebhetri.Isixhobo sokurisayikilisha ibhetri yeLithium singanceda ukuhlangabezana nale mfuno ngokubonelela ngendlela ethembekileyo nengabiziyo yokufumana kwakhona imathiriyeli exabisekileyo kwiibhetri ezisetyenzisiweyo.

Nangona kunjalo, kubalulekile ukuqaphela ukuba ukwenziwa kwakhona kwebhetri ye-lithium kuseyishishini elitsha noko, kwaye kukho imiceli mngeni ekufuneka yoyiswe malunga nokuphuhlisa iinkqubo zokurisayikilisha ezisebenzayo nezingabizi kakhulu.Ukongeza, ukuphathwa ngokufanelekileyo kunye nokulahlwa kwenkunkuma yebhetri kubalulekile ukuphepha iingozi zendalo kunye nempilo.Ngoko ke, imimiselo efanelekileyo kunye namanyathelo okhuseleko kufuneka abekhona ukuze kuqinisekiswe ukuphathwa ngokufanelekileyo kunye nokuhlaziywa kweebhetri ze-lithium.