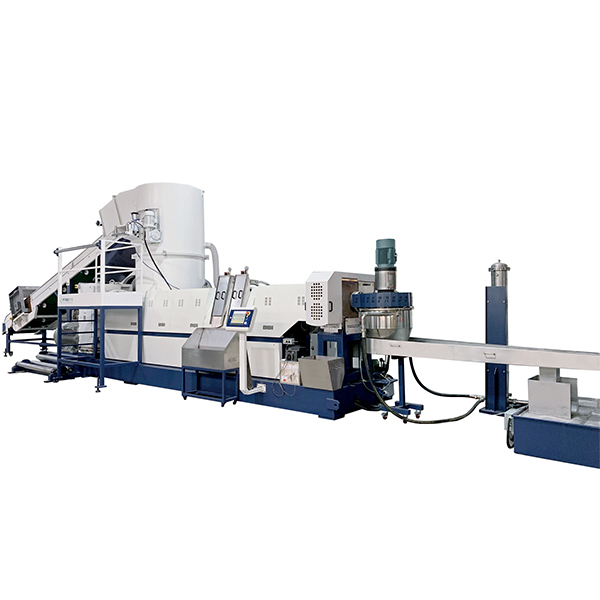

Umatshini we-BOPP wokwenza umatshini wokugranula ifilimu

Umatshini wefilimu we-BOPP we-granulating udibanisa imisebenzi yokutyumza, ukudibanisa, i-plasticization kunye ne-granulation, kwaye ifanelekile kwi-plastic recycling kunye neenkqubo ze-granulation.I-BOPP ifilimu yegranulator iyisisombululo esithembekileyo nesisebenzayo sokubuyisela kwakhona kunye ne-pelletizing yefilimu yeplastiki, i-raffia fiber, i-filament, isikhwama, isikhwama esilukiweyo kunye nempahla ye-foam.Imveliso yokugqibela eveliswa yiFangsheng BOPP ifilimu yegranulator / i-pelletizer ikwimo yeegranules / iigranules, ezinokuthi zifakwe ngokuthe ngqo kumgca wokuvelisa ukukhutshwa kwefilimu, i-extrusion yepayipi kunye ne-injection yeplastiki, njl.

Lo matshini luhlobo lomatshini wokurisayikilisha weplastiki.Inokudlulisela imatrial yenkunkuma kwiipellets eziluncedo ukwenzela imveliso eyongezelelweyo.

Iimpawu zoomatshini bokwenza ifilimu yeBOPP:

1. Umatshini we-BOPP wefilimu we-granulating unokulungelelaniswa kakuhle, phantse zonke iintlobo zeplastiki yegranulation eqhelekileyo inokulungiswa.Umlinganiselo wokusetyenziswa kwamandla omatshini wokubuyisela iplastiki uphantsi.Umgangatho wemveliso yemveliso kunye nenzuzo ebanzi yokhuphiswano ibonakala.

2. Ekupheleni kombhobho we-screw, i-recycling granulator efakwe i-double-column fast hydraulic non-stop screen changer inokucoca ngokufanelekileyo ukungcola kwiplastiki enyibilikayo.

3. Amasuntswana amatsha emva kokubunjwa kokuvuthela okanye isitofu angasetyenziselwa ukwenza iimveliso zeplastiki ezintsha.Umzekelo, iifilimu zeplastiki, iingxowa zeplastiki, iibhotile zeplastiki, iipalethi zeplastiki, iibhokisi zeplastiki, imigqomo yeplastiki, njl.

4. Inkqubo yokusabalalisa amandla ngokuzenzekelayo iyamkelwa ukuqinisekisa ukusebenza okuqhelekileyo kwemoto.

Iifilimu ze-BOPP ziRecycling kuMatshini woBuchule beParameter:

Eqhelekileyo:

| Umzekelo | ML85 | ML100 | ML130 | ML160 | ML180 |

| Imveliso(kg/h) | 120-180 | 180-300 | 400-500 | 600-800 | 800-1000 |

Imveliso ephezulu, ukusetyenziswa okuphantsi:

| Umzekelo | ML100B | ML130B | ML160B | ML180B |

| Imveliso(kg/h) | 350-400 | 500-600 | 600-800 | 1000-1100 |

Iifilimu ze-BOPP zokuRisayikilishwa koMatshini weGranulating Inkqubo yokuSebenza:

ifilim yebopp→isihambisi sebhanti→isigqubuthelo→isikrufu esinye →isijija sesikrini soxinzelelo →isixokelelwano sepelletizing →usasazo lomoya →ugcino lwesisele

I-BOPP Film iNgcaciso yesiXhobo seGranulating:

Iringi yamanzi Die-face cutting system

I-water-ring die-face-face/Iendlela zokusika i-Strand zihlala zamkelwa.Kwinkqubo yokusika i-water-ring die-face-face cutting, ii-rotary cutting blades ziya kulungelelana nge-pneumatically ngokupheleleyo kwaye ngokusondeleyo kwi-face-face surface ukuqinisekisa ukusika ngokufanelekileyo.Isantya sokujikeleza kwee-blades sihlengahlengiswa ngokuzenzekelayo yinkqubo yemodyuli ngokoxinzelelo olunyibilikayo ebusweni bokufa.

ividiyo:

Nawuphi na umbuzo, nceda uqhagamshelane nathi ngokukhululekileyo.

Umatshini wokurisayikilisha weplastiki luhlobo lwezixhobo ezisetyenziselwa ukusetyenzwa ngokutsha kwenkunkuma yeplastiki kwiigranuli okanye iipeliti ezinokuthi ziphinde zisetyenziswe ekwenzeni iimveliso zeplastiki ezintsha.Umatshini usebenza ngokucofa okanye ukucola inkunkuma yeplastiki ibe ngamaqhekeza amancinci, emva koko uyinyibilikise kwaye uyikhuphe ngokufa ukwenza iipellets okanye iigranules.

Kukho iintlobo ezahlukeneyo zeplastiki zokurisayikilisha kunye noomatshini begranulating abakhoyo, kubandakanywa isikrufu esinye kunye ne-twin-screw extruders.Abanye oomatshini baquka iimpawu ezongezelelweyo ezifana nezikrini zokususa ukungcola kwinkunkuma yeplastiki okanye iinkqubo zokupholisa ukuqinisekisa ukuba iipelisi ziqiniswe ngokufanelekileyo.Umatshini wokuhlamba ibhotile ye-PET, i-PP elukiweyo yeengxowa zomgca wokuhlamba

Oomatshini beplastiki bokurisayikilisha kunye noomatshini bokwenza igranulayitha baqhele ukusetyenziswa kwimizi-mveliso eyenza isixa esikhulu senkunkuma yeplastiki, njengokupakishwa, iimoto kunye nokwakha.Ngokuphinda kusetyenziswe inkunkuma yeplastiki, aba matshini banceda ukunciphisa impembelelo yokusingqongileyo yokulahlwa kweplastiki kunye nokugcina izixhobo ngokusebenzisa izinto ebezinokulahlwa ngenye indlela.

Isixhobo sokurisayikilisha ibhetri yeLithium luhlobo lwezixhobo ezisetyenziselwa ukurisayikilisha nokubuyisela izinto ezixabisekileyo kwiibhetri ze-lithium-ion, eziqhele ukusetyenziswa kwizixhobo zombane ezifana nee-smartphones, iilaptops, kunye nezithuthi zombane.Isixhobo sisebenza ngokuqhekeza iibhetri kwiindawo zazo, njenge-cathode kunye nemathiriyeli ye-anode, isisombululo se-electrolyte, kunye neefoyile zetsimbi, kwaye emva koko zahlula kwaye zihlambulule ezi mathiriyeli ukuze zisetyenziswe kwakhona.

Kukho iintlobo ezahlukeneyo zezixhobo zokuhlaziya ibhetri ye-lithium ezikhoyo, kubandakanywa iinkqubo ze-pyrometallurgical, iinkqubo ze-hydrometallurgical, kunye neenkqubo zoomatshini.Iinkqubo zePyrometallurgical zibandakanya ukusetyenzwa kobushushu obuphezulu beebhetri ukubuyisela iintsimbi ezinje ngobhedu, nickel, kunye necobalt.Iinkqubo ze-Hydrometallurgical zisebenzisa izisombululo zekhemikhali ukunyibilikisa amacandelo ebhetri kunye nokubuyisela iintsimbi, ngelixa iinkqubo zoomatshini zibandakanya ukuqhekeza kunye nokugaya iibhetri ukwahlula izixhobo.

Isixhobo sokurisayikilisha ibhetri yeLithium sibalulekile ekunciphiseni impembelelo yokusingqongileyo yokulahlwa kwebhetri kunye nokugcina izixhobo ngokufumana kwakhona iintsimbi ezixabisekileyo kunye nezinto ezinokuthi ziphinde zisetyenziswe kwiibhetri ezintsha okanye ezinye iimveliso.

Ukongeza kwiinzuzo zokusingqongileyo kunye nokugcinwa kwezibonelelo, izixhobo zokuphinda zisetyenziswe ibhetri ye-lithium nazo zineenzuzo zoqoqosho.Ukufumana kwakhona isinyithi esixabisekileyo kunye nezinto ezivela kwiibhetri ezisetyenzisiweyo kunokunciphisa iindleko zokuvelisa iibhetri ezintsha, kunye nokudala imithombo emitsha yengeniso kwiinkampani ezibandakanyekayo kwinkqubo yokubuyisela kwakhona.

Ngaphaya koko, ukwanda kwemfuno yezithuthi zombane kunye nezinye izixhobo zombane kuqhuba imfuneko yoshishino olusebenzayo noluzinzileyo lokurisayikilisha kweebhetri.Isixhobo sokurisayikilisha ibhetri yeLithium singanceda ukuhlangabezana nale mfuno ngokubonelela ngendlela ethembekileyo nengabiziyo yokufumana kwakhona imathiriyeli exabisekileyo kwiibhetri ezisetyenzisiweyo.

Nangona kunjalo, kubalulekile ukuqaphela ukuba ukwenziwa kwakhona kwebhetri ye-lithium kuseyishishini elitsha noko, kwaye kukho imiceli mngeni ekufuneka yoyiswe malunga nokuphuhlisa iinkqubo zokurisayikilisha ezisebenzayo nezingabizi kakhulu.Ukongeza, ukuphathwa ngokufanelekileyo kunye nokulahlwa kwenkunkuma yebhetri kubalulekile ukuphepha iingozi zendalo kunye nempilo.Ngoko ke, imimiselo efanelekileyo kunye namanyathelo okhuseleko kufuneka abekhona ukuze kuqinisekiswe ukuphathwa ngokufanelekileyo kunye nokuhlaziywa kweebhetri ze-lithium.