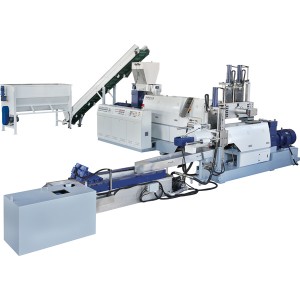

I-extruder Screw enye yeplastiki yokuphinda isetyenziswe inkqubo yepelletizing

Isikrufu esinye se-extruder yeplastiki yokuphinda isetyenziswe inkqubo yepelletizing

I-screw extruders enye iphuhliselwe uhlobo olusisiseko lwe-extruder olunyibilika ngokulula kwaye lwenze imathiriyeli.Ngenxa yeendleko zabo eziphantsi, uyilo olulula, ukugoba, kunye nokuthembeka, oomatshini bokukhupha isikhonkwane esinye sesinye sezona matshini zidumileyo zokukhupha kwaye zisetyenziswa ngokubanzi kuzo zonke iintlobo zeplastiki eziphinda zisetyenziswe.Eyona nto ithandwayo yiPP kunye ne-PE yokurisayikilisha.

Uthotho lwe-SJ yinkqubo yokwenziwa ngokutsha kwe-screw extruder yokuphinda isetyenziswe yinkqubo ekhethekileyo nethembekileyo elungele ukurisayikilishwa nokuphinda kugaywe kwakhona.Idibanisa umsebenzi weplastiki kunye ne-pelletizing ukuya kwinqanaba elinye.Ingasetyenziselwa ukurisayikilisha iiplastiki, ezifana nePE etyumkileyo, iibhotile zePP kunye neeflakes zegubu kwaye zihlanjwe kwaye zicudiswe iifilimu ze-PE ezomileyo, kunye ne-ABS, i-PS, i-PP evela kwi-pallets yenkunkuma, izitulo, izixhobo zombane njl njl. Umthamo womatshini wokurisayikilisha ibe ezahlukeneyo ukusuka 100-1100kg/h.

1.Kwiiplastiki eziqinileyo ze-pelletizing, ezifana ne-Screw of extruder yenzelwe ngokukodwa iiplastiki ezingcolileyo ezithelekisekayo kunye nokuhluzwa kabini.Inokwenza i-PP, i-PE, i-ABS kunye neeplastiki eziqinileyo ze-PC kunye ne-PP ehlanjiweyo, iifilimu ze-PE.Umphanda unokuba kukupholisa umoya okanye ukupholisa amanzi.Kwaye uhlobo lwe-pelletizing lunokunkcenkceshela i-pelletizing, i-strand pelletizing kunye ne-pelletizing engaphantsi kwamanzi.

2.Ukomisa iifilimu ze-PE PP ezihlanjwe kwaye zikhanyiwe.Ubumanzi bezinto eziluhlaza kufuneka bube ngaphakathi kwe-5-7%.Ikunye ne-silo enkulu ene-screw ukuhambisa ngokuzenzekelayo izinto kwibhanti, eya kudlulisela i-raw material kwi-extruder.

Umatshini unezigaba ezibini unokucoca ngokufanelekileyo ukungcola kwaye kulula ukupelisa izinto ezikrwada kwindlela yokunkcenkceshela i-pelletizing.

Ngokwesicelo somthengi, sinokwenza inkqubo ye-pelletizing ibe yi-strand pelletizing okanye i-pelletizing engaphantsi kwamanzi.

Uphawu:

Ngoyilo oluhambele phambili, imveliso ephezulu, iplastiki elungileyo, ukusetyenziswa okuphantsi, kunye nokuhanjiswa kwegiya ye-spline, ineengenelo ezinje ngengxolo ephantsi, ukubaleka kwakudala, amandla okuthwala kunye nobomi obude.

I-screw extruder yokuphinda isetyenziswe inkqubo ye-pelletizing inikezela ngesisombululo esineendleko kunye nesisebenzayo sokuphinda kusetyenziswe inkunkuma yeplastiki, njengoko iyakwazi ukucubungula uluhlu olubanzi lwezinto zeplastiki kunye nokuvelisa iipellet eziphezulu ezinokuthi zisetyenziswe kwizicelo ezahlukeneyo.Ikwanceda ekunciphiseni ubungakanani benkunkuma yeplastiki ephela kwindawo yokulahla inkunkuma okanye kwimo engqongileyo, ibe negalelo kwinkqubo yokwenziwa ezinzileyo kunye nelungele ukuphilisana kwendalo.

Imodeli ye-extruder yeqonga elinye

| Umzekelo | SJ100 | SJ120 | SJ140 | SJ150 | SJ160 | SJ180 | SJ200 |

| I-Screw diameter | 100 | 120 | 140 | 150 | 160 | 180 | 200 |

| L/D | 18-42 | 18-42 | 18-42 | 18-42 | 18-42 | 18-42 | 18-42 |

| Isantya sokujikeleza | 10-150 | 10-150 | 10-150 | 10-150 | 10-150 | 10-150 | 10-150 |

| Imveliso(kg/h) | 250-350 | 300-400 | 500-600 | 600-800 | 800-1000 | 900-1200 | 1000-1500 |

Imodeli ye-extruder yeqonga ezimbini

| Umzekelo | SJ130/140 | SJ140/150 | SJ150/160 | SJ160/180 | SJ200/200 |

| Imveliso(kg/h) | 500 | 600 | 800 | 1000 | ont-ubungakanani: phakathi;”>1000-1200 |

Umatshini wokurisayikilisha weplastiki luhlobo lwezixhobo ezisetyenziselwa ukusetyenzwa ngokutsha kwenkunkuma yeplastiki kwiigranuli okanye iipeliti ezinokuthi ziphinde zisetyenziswe ekwenzeni iimveliso zeplastiki ezintsha.Umatshini usebenza ngokucofa okanye ukucola inkunkuma yeplastiki ibe ngamaqhekeza amancinci, emva koko uyinyibilikise kwaye uyikhuphe ngokufa ukwenza iipellets okanye iigranules.

Kukho iintlobo ezahlukeneyo zeplastiki zokurisayikilisha kunye noomatshini begranulating abakhoyo, kubandakanywa isikrufu esinye kunye ne-twin-screw extruders.Abanye oomatshini baquka iimpawu ezongezelelweyo ezifana nezikrini zokususa ukungcola kwinkunkuma yeplastiki okanye iinkqubo zokupholisa ukuqinisekisa ukuba iipelisi ziqiniswe ngokufanelekileyo.Umatshini wokuhlamba ibhotile ye-PET, i-PP elukiweyo yeengxowa zomgca wokuhlamba

Oomatshini beplastiki bokurisayikilisha kunye noomatshini bokwenza igranulayitha baqhele ukusetyenziswa kwimizi-mveliso eyenza isixa esikhulu senkunkuma yeplastiki, njengokupakishwa, iimoto kunye nokwakha.Ngokuphinda kusetyenziswe inkunkuma yeplastiki, aba matshini banceda ukunciphisa impembelelo yokusingqongileyo yokulahlwa kweplastiki kunye nokugcina izixhobo ngokusebenzisa izinto ebezinokulahlwa ngenye indlela.

Isixhobo sokurisayikilisha ibhetri yeLithium luhlobo lwezixhobo ezisetyenziselwa ukurisayikilisha nokubuyisela izinto ezixabisekileyo kwiibhetri ze-lithium-ion, eziqhele ukusetyenziswa kwizixhobo zombane ezifana nee-smartphones, iilaptops, kunye nezithuthi zombane.Isixhobo sisebenza ngokuqhekeza iibhetri kwiindawo zazo, njenge-cathode kunye nemathiriyeli ye-anode, isisombululo se-electrolyte, kunye neefoyile zetsimbi, kwaye emva koko zahlula kwaye zihlambulule ezi mathiriyeli ukuze zisetyenziswe kwakhona.

Kukho iintlobo ezahlukeneyo zezixhobo zokuhlaziya ibhetri ye-lithium ezikhoyo, kubandakanywa iinkqubo ze-pyrometallurgical, iinkqubo ze-hydrometallurgical, kunye neenkqubo zoomatshini.Iinkqubo zePyrometallurgical zibandakanya ukusetyenzwa kobushushu obuphezulu beebhetri ukubuyisela iintsimbi ezinje ngobhedu, nickel, kunye necobalt.Iinkqubo ze-Hydrometallurgical zisebenzisa izisombululo zekhemikhali ukunyibilikisa amacandelo ebhetri kunye nokubuyisela iintsimbi, ngelixa iinkqubo zoomatshini zibandakanya ukuqhekeza kunye nokugaya iibhetri ukwahlula izixhobo.

Isixhobo sokurisayikilisha ibhetri yeLithium sibalulekile ekunciphiseni impembelelo yokusingqongileyo yokulahlwa kwebhetri kunye nokugcina izixhobo ngokufumana kwakhona iintsimbi ezixabisekileyo kunye nezinto ezinokuthi ziphinde zisetyenziswe kwiibhetri ezintsha okanye ezinye iimveliso.

Ukongeza kwiinzuzo zokusingqongileyo kunye nokugcinwa kwezibonelelo, izixhobo zokuphinda zisetyenziswe ibhetri ye-lithium nazo zineenzuzo zoqoqosho.Ukufumana kwakhona isinyithi esixabisekileyo kunye nezinto ezivela kwiibhetri ezisetyenzisiweyo kunokunciphisa iindleko zokuvelisa iibhetri ezintsha, kunye nokudala imithombo emitsha yengeniso kwiinkampani ezibandakanyekayo kwinkqubo yokubuyisela kwakhona.

Ngaphaya koko, ukwanda kwemfuno yezithuthi zombane kunye nezinye izixhobo zombane kuqhuba imfuneko yoshishino olusebenzayo noluzinzileyo lokurisayikilisha kweebhetri.Isixhobo sokurisayikilisha ibhetri yeLithium singanceda ukuhlangabezana nale mfuno ngokubonelela ngendlela ethembekileyo nengabiziyo yokufumana kwakhona imathiriyeli exabisekileyo kwiibhetri ezisetyenzisiweyo.

Nangona kunjalo, kubalulekile ukuqaphela ukuba ukwenziwa kwakhona kwebhetri ye-lithium kuseyishishini elitsha noko, kwaye kukho imiceli mngeni ekufuneka yoyiswe malunga nokuphuhlisa iinkqubo zokurisayikilisha ezisebenzayo nezingabizi kakhulu.Ukongeza, ukuphathwa ngokufanelekileyo kunye nokulahlwa kwenkunkuma yebhetri kubalulekile ukuphepha iingozi zendalo kunye nempilo.Ngoko ke, imimiselo efanelekileyo kunye namanyathelo okhuseleko kufuneka abekhona ukuze kuqinisekiswe ukuphathwa ngokufanelekileyo kunye nokuhlaziywa kweebhetri ze-lithium.