Ixabiso elikhethekileyo lePlastiki yePlastiki ye-PE PP yoKuhlamba ifilim kunye nokuRecycling kwiGranulating Machine Line

Iimveliso zethu zichongiwe ngokubanzi kwaye zithembeke ngabathengi kwaye ziya kwanelisa rhoqo ukuphuhlisa iminqweno yezoqoqosho kunye nentlalontle kwiXabiso eliKhethekileyo lePlastiki yePlastiki ye-PE PP yokuhlamba iFilimu kunye nokuHlaziya uMshini weGranulating Line, Njengoko siqhubela phambili, sibambe iliso kwiimveliso zethu ezihlala zikhula. uluhlu kunye nokwenza uphuculo kwiinkampani zethu.

Iimveliso zethu zichongiwe ngokubanzi kwaye zithembeke ngabathengi kwaye ziya kwanelisa rhoqo ukuphuhlisa iminqweno yezoqoqosho nentlaloChina iplastiki Granulating machine, Ukurisayikilisha Umatshini wokwenza iGranulating, Sigxile ekuboneleleni ngenkonzo kubaxumi bethu njengento ephambili ekomelezeni ubudlelwane bethu bexesha elide.Ubukho bethu obuqhubekekayo bempahla yodidi oluphezulu ngokudityaniswa nenkonzo yethu ebalaseleyo yokuthengisa kwangaphambili nasemva kokuthengisa kuqinisekisa ukhuphiswano olomeleleyo kwimakethi ekhulayo yehlabathi.

Ividiyo yemveliso:

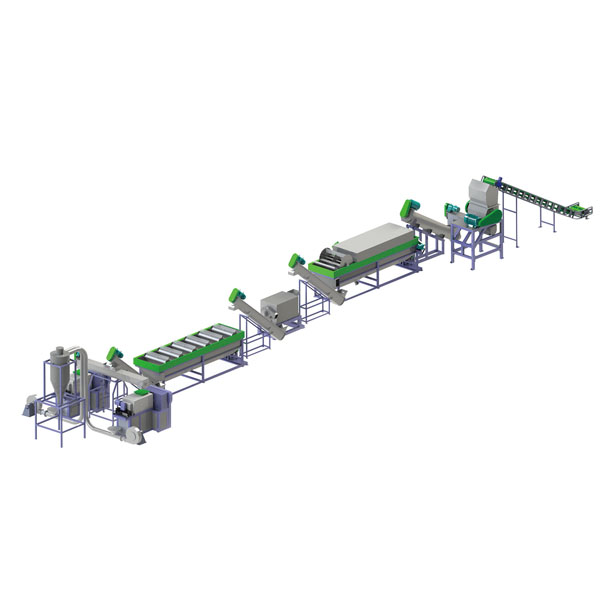

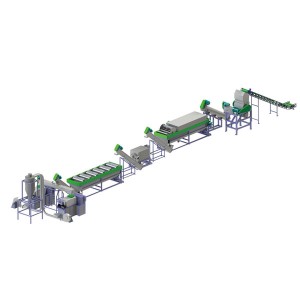

I-PP, ifilimu ye-PE kunye ne-PP elukiweyo iingxowa inkqubo yokurisayikilisha

Uyilo:

1.Ibhanti yokuhambisa

2.Isityuli

3.Ukuhlamba ukukhuhlana okuthe tye

4.Isantya esiphezulu sokuhlamba i-friction

5.Itanki edadayo

6.Isikrufu sokulayisha

7. Ukukhupha amanzi

8.Isikrufu sokulayisha

9.Iwasha edadayo

10.Isikrufu sokulayisha

11.Iplastic squeezer dryer

Owona matshini wokuhlamba uphambili uneempawu:

A.Ukuhlanjwa kwe-Horizontal Friction

Yenzelwe ukususa ngokufanelekileyo isanti kunye nelebhile intonga kwiifilimu.Wongeza amanzi okuhlamba.

B.Isantya esiphezulu sokuhlamba i-friction

Yenzelwe ukususa isanti iilebhile zincamathele kwiifilim.Iyakongeza amanzi ukuhlamba. (umfanekiso)

C.Itanki edadayo

Iya kudada impahla ekrwada.Kwaye ngokwemeko yezinto ezikrwada, sinokongeza ivalve ye-pneumatic ukukhupha inkunkuma kunye nesanti.Uyilo lwetsheyini yentsimbi engatyiwayo yokulahla inkunkuma ukugcina amanzi.(umfanekiso)

D.Plastiki dewatering machine

Umatshini wokuhlamba amanzi ususa amanzi amdaka, umhlaba, kunye ne-pulp emva kwetanki yokuhlamba edadayo, ukuze kuqinisekiswe ukuba amanzi kwitanki yokuhlamba elandelayo acocekile ngaloo ndlela aphucula ukusebenza kokucoca.

Isantya somatshini wokukhupha amanzi yi-2000rpm eqhuba kakuhle kunye nengxolo ephantsi. (umfanekiso)

E.Plastic squeezer dryer

Iya kusetyenziswa ekomisweni kwezinto ekrwada kwindlela yokuhlamba.Susa ngokufanelekileyo amanzi kwaye ugcine ukufuma ngaphakathi kwe-5%.Iza kuphucula kakhulu umgangatho weplasitiki elandelayo yokusetyenzwa kwepelletizing.(Sisqueezer Umfanekiso)

Iimodeli:

| Umzekelo | NG300 | NG320 | NG350 |

| Imveliso (kg/h) | 500 | 700 | 1000 |

| Impahla engekasilwa | Iifilimu ze-PE kunye nomsonto, iifilimu zePP kunye nomsonto | Iifilimu ze-PE kunye nomsonto, iifilimu zePP kunye nomsonto | Iifilimu ze-PE kunye nomsonto, iifilimu zePP kunye nomsonto |

(ukubonelela ngomfanekiso wesqueezer kunye nemifanekiso ekrwada)

Iimveliso zethu zichongiwe ngokubanzi kwaye zithembeke ngabathengi kwaye ziya kwanelisa rhoqo ukuphuhlisa iminqweno yezoqoqosho kunye nentlalontle kwiXabiso eliKhethekileyo lePlastiki yePlastiki ye-PE PP yokuhlamba iFilimu kunye nokuHlaziya uMshini weGranulating Line, Njengoko siqhubela phambili, sibambe iliso kwiimveliso zethu ezihlala zikhula. uluhlu kunye nokwenza uphuculo kwiinkampani zethu.

Ixabiso elikhethekileyo leChina iplastiki Granulating machine, Ukurisayikilisha Umatshini wokwenza iGranulating, Sigxile ekuboneleleni ngenkonzo kubaxumi bethu njengento ephambili ekomelezeni ubudlelwane bethu bexesha elide.Ubukho bethu obuqhubekekayo bempahla yodidi oluphezulu ngokudityaniswa nenkonzo yethu ebalaseleyo yokuthengisa kwangaphambili nasemva kokuthengisa kuqinisekisa ukhuphiswano olomeleleyo kwimakethi ekhulayo yehlabathi.

Umatshini wokurisayikilisha weplastiki luhlobo lwezixhobo ezisetyenziselwa ukusetyenzwa ngokutsha kwenkunkuma yeplastiki kwiigranuli okanye iipeliti ezinokuthi ziphinde zisetyenziswe ekwenzeni iimveliso zeplastiki ezintsha.Umatshini usebenza ngokucofa okanye ukucola inkunkuma yeplastiki ibe ngamaqhekeza amancinci, emva koko uyinyibilikise kwaye uyikhuphe ngokufa ukwenza iipellets okanye iigranules.

Kukho iintlobo ezahlukeneyo zeplastiki zokurisayikilisha kunye noomatshini begranulating abakhoyo, kubandakanywa isikrufu esinye kunye ne-twin-screw extruders.Abanye oomatshini baquka iimpawu ezongezelelweyo ezifana nezikrini zokususa ukungcola kwinkunkuma yeplastiki okanye iinkqubo zokupholisa ukuqinisekisa ukuba iipelisi ziqiniswe ngokufanelekileyo.Umatshini wokuhlamba ibhotile ye-PET, i-PP elukiweyo yeengxowa zomgca wokuhlamba

Oomatshini beplastiki bokurisayikilisha kunye noomatshini bokwenza igranulayitha baqhele ukusetyenziswa kwimizi-mveliso eyenza isixa esikhulu senkunkuma yeplastiki, njengokupakishwa, iimoto kunye nokwakha.Ngokuphinda kusetyenziswe inkunkuma yeplastiki, aba matshini banceda ukunciphisa impembelelo yokusingqongileyo yokulahlwa kweplastiki kunye nokugcina izixhobo ngokusebenzisa izinto ebezinokulahlwa ngenye indlela.

Isixhobo sokurisayikilisha ibhetri yeLithium luhlobo lwezixhobo ezisetyenziselwa ukurisayikilisha nokubuyisela izinto ezixabisekileyo kwiibhetri ze-lithium-ion, eziqhele ukusetyenziswa kwizixhobo zombane ezifana nee-smartphones, iilaptops, kunye nezithuthi zombane.Isixhobo sisebenza ngokuqhekeza iibhetri kwiindawo zazo, njenge-cathode kunye nemathiriyeli ye-anode, isisombululo se-electrolyte, kunye neefoyile zetsimbi, kwaye emva koko zahlula kwaye zihlambulule ezi mathiriyeli ukuze zisetyenziswe kwakhona.

Kukho iintlobo ezahlukeneyo zezixhobo zokuhlaziya ibhetri ye-lithium ezikhoyo, kubandakanywa iinkqubo ze-pyrometallurgical, iinkqubo ze-hydrometallurgical, kunye neenkqubo zoomatshini.Iinkqubo zePyrometallurgical zibandakanya ukusetyenzwa kobushushu obuphezulu beebhetri ukubuyisela iintsimbi ezinje ngobhedu, nickel, kunye necobalt.Iinkqubo ze-Hydrometallurgical zisebenzisa izisombululo zekhemikhali ukunyibilikisa amacandelo ebhetri kunye nokubuyisela iintsimbi, ngelixa iinkqubo zoomatshini zibandakanya ukuqhekeza kunye nokugaya iibhetri ukwahlula izixhobo.

Isixhobo sokurisayikilisha ibhetri yeLithium sibalulekile ekunciphiseni impembelelo yokusingqongileyo yokulahlwa kwebhetri kunye nokugcina izixhobo ngokufumana kwakhona iintsimbi ezixabisekileyo kunye nezinto ezinokuthi ziphinde zisetyenziswe kwiibhetri ezintsha okanye ezinye iimveliso.

Ukongeza kwiinzuzo zokusingqongileyo kunye nokugcinwa kwezibonelelo, izixhobo zokuphinda zisetyenziswe ibhetri ye-lithium nazo zineenzuzo zoqoqosho.Ukufumana kwakhona isinyithi esixabisekileyo kunye nezinto ezivela kwiibhetri ezisetyenzisiweyo kunokunciphisa iindleko zokuvelisa iibhetri ezintsha, kunye nokudala imithombo emitsha yengeniso kwiinkampani ezibandakanyekayo kwinkqubo yokubuyisela kwakhona.

Ngaphaya koko, ukwanda kwemfuno yezithuthi zombane kunye nezinye izixhobo zombane kuqhuba imfuneko yoshishino olusebenzayo noluzinzileyo lokurisayikilisha kweebhetri.Isixhobo sokurisayikilisha ibhetri yeLithium singanceda ukuhlangabezana nale mfuno ngokubonelela ngendlela ethembekileyo nengabiziyo yokufumana kwakhona imathiriyeli exabisekileyo kwiibhetri ezisetyenzisiweyo.

Nangona kunjalo, kubalulekile ukuqaphela ukuba ukwenziwa kwakhona kwebhetri ye-lithium kuseyishishini elitsha noko, kwaye kukho imiceli mngeni ekufuneka yoyiswe malunga nokuphuhlisa iinkqubo zokurisayikilisha ezisebenzayo nezingabizi kakhulu.Ukongeza, ukuphathwa ngokufanelekileyo kunye nokulahlwa kwenkunkuma yebhetri kubalulekile ukuphepha iingozi zendalo kunye nempilo.Ngoko ke, imimiselo efanelekileyo kunye namanyathelo okhuseleko kufuneka abekhona ukuze kuqinisekiswe ukuphathwa ngokufanelekileyo kunye nokuhlaziywa kweebhetri ze-lithium.