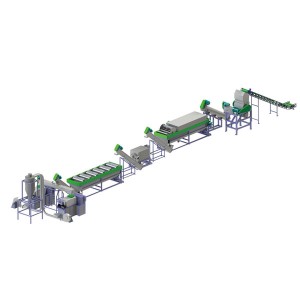

IPast-Agriculture Film Recycle Washing Plant

I-Post-Agriculture PE Film Washing Line

Ukusika ifilimu yePlastiki, ukuhlamba, umatshini wokuphinda usebenziseke kwakhona onemveliso ephezulu kunye nobuchule obugqwesileyo obucocekileyo (500kg / h ukuya kwi-6500kg / h)

Umgca opheleleyo wokurisayikilisha weplastiki usetyenziselwa ukutyumza, ukuhlamba, ukukhupha amanzi kunye nokomisa ifilimu yePP/PE, isikhwama esilukiweyo sePP.

Iprosesa imathiriyeli:

Lo mgca wokuhlamba ungasetyenziselwa isikhwama esilukiweyo sePP, ifilimu kunye nengxowa yenkunkuma ye-PE, ifilimu, imathiriyeli yokupakisha kunye nezinye izinto ezikhululekileyo, ifilimu yezolimo (1mm), ifilimu ye-LDPE yoshishino enobisi kunye nomgubo, ifilimu ye-LDPE yendlu eluhlaza.

Inkqubo yomsebenzi:

Ibhanti yokuhambisa-i-crusher-spiral feeder-friction washer-spiral feeder-edadayo itanki-spiral feeder (layisho)-spiral feeder (khutshelwa)-iwasha eshushu-friction iwasha-spiral feeder-itanki edadayo-spiral feeder-centrifugal dewatering-pipe dryer- silo

| Bale Breaking | Ukunceda uthutho lwefilimu, ngakumbi nangakumbi umthengisi weplastiki yenkunkuma echithayo ukhetha ukucinezela ifilimu kwibheyile.Kuba i-recycler yenza iplastiki yokurisayikilisha, bayayidingaYaphula ibhali.Umsiki weHydraulicNgokubeka ibhali yonke, i-hydraulic cutter yinqumle ibe yibhloko encinci. I-pre-shredderUkwaphula ibheyile ngeshafti yangaphakathi kunye ne-output scrap ende |

| Cukungxama | Iplastiki yeGranulator / i-crusherukusika ngakumbi inkunkuma ende ibe yinkunkuma encinciI-crusher emanzi ineempembelelo ezi-2Kwelinye icala, ukuhlamba inkunkuma etyumkileyo ngamanzi, kwelinye icala, amanzi anokwehlisa iqondo lobushushu ngee-crusher cutters (i-bere-resistance).I-Crusher inokuxhotyiswa ngepleyiti yokusebenzaIsebenza ngokulula kunye nabasiki ababukhali |

| Ukuhlamba kwangaphambili | Iwasha yangaphambiliLo matshini ikakhulu ukucoca ifilimu yeplastiki ye-PE / PP / PET kunye neeflakes ezithi emva kokutyumza, ukucoca ukungcola okuxutywe kwifilimu.Iishafu ezimbini zangaphakathi ezinkulu ezijikelezayo kwitanki ejikelezayo, imathiriyeli iya kumbambatha kwaye ihlanjwe ngokwahlula inkunkuma encangathi. Umatshini wokuhlamba ifilim (ishafti ezimbini ezijikelezayo)Ukutya okukhethekileyo kunye noyilo lweblade yokuhlamba yesayizi enkulu yefilimu yokuhlamba kwangaphambili, isikrini sinokususa uninzi lwesanti emdaka kunye ne-99%.Inokukhusela iimela ze-crusher ukuba ziqhube ixesha elide kwaye zisebenze ngakumbi.Ifilimu yenkunkuma ngomatshini wokuvasa kwangaphambili inokwehlisa ubumdaka obungama-80%.Umtshini unokuba manzi kwaye womile ukuhlamba. Trommelkunye negubu elijikelezayo elijikelezayo, inkunkuma enkulu iya kuhluzwa ngomngxuma wegubu.Inkunkuma enkulu iya kukhutshelwa ngaphandle ngebhanti elisezantsi. |

| Ukuhlamba | Itanki edadayoHlamba kwaye uhlukanise izinto ngokuxhuzula okubonakalayo kunye nobunzima bamanzi.Ukonga amanzi ngokusebenzisa ityathanga lentsimbi engatyiwa, kunye nevalve yokuvula umoya |

| Ukukhupha amanzi | Isomisi se-Centrifugal esithe tyabaLo matshini usetyenziselwa ukucoca ifilimu yeplastiki yokucoca, amandla e-centrifugal ukusuka kwisantya esiphezulu sokujikeleza kwi-master shaft ephosa ifilimu yeplastiki kunye namanzi kwisikrini, kwaye amanzi akhutshwe kwisikrini.Lo matshini usebenza kakuhle ekomisweni kunye nokusebenza okuphezulu.Umbhobho womisoNgomoya oshushu ngemibhobho, imathiriyeli iyoma nge-20% yesiqulatho samanzi. |

| Ukucudisa & Ukudibanisa | I-squeezer kunye ne-agglomeratorubume bangaphakathi:esinye isikrufu esikhulu esifakwe kwisicinezeli.nge-screw ejikelezayo, izinto ziya kutyhala kwaye zicinezele.ngeli xesha, amanzi ayaphuma kwisihluzo.emva koko, kunye nobushushu obuvela kwi-friction yenkunkuma yezinto, izinto ziya kufudumeza zibe yi-semi-melting.emva koko, nge-die/mold, i-mterial iya kucinezelwa ngobushushu obuphezulu.emva koko, izinto zihamba nge-pelletizing system, kwaye zikhuphe i-scrap eqinile.Lo matshini ungaphantsi kokusetyenziswa kwamandla kunye nokusebenza kakuhle kokumisa, umxholo womswakama wezinto eziphumayo unokulawulwa phakathi kwe-5-10%. |

| Umthamo | 300-2000 kg / h |

| Isicelo | ifilimu yokupakisha ukutya, ifilimu yezolimo, indlu eluhlaza kusetyenziswa ifilimu esetyenziswa kwintsimi yeoli, isikhwama sePP, ifilimu ye-PE, isikhwama esilukiweyo, ifilimu ye-LDPE eshwabeneyo okanye ifilimu eprintiweyo enzima, ingxowa yesamente, ibhegi enamafutha, ingxowa emdaka. |

| Inkcazo | IShredder yePlastiki/ Isityuli sePlastiki, Iwasha yokuFikisana ngesantya esiphezulu, Iwasha yokukhupha amanzi eCentrifugal, iSpiral Feeder, iTanki edadayo, iSpiral Feeder, iiShafti ezimbini eziBolisayo, iSisqueezer okanye isisqueezer kunye neAgglomerator.Isebenza ngokulula ngogcino lwamandla |

| Uhlobo Lwemveliso | ukutyumza, ukuhlamba, ukukhupha amanzi, ukomisa, ukugalela kunye nokupakishwa Ukufuma kwesiphumo sokugqibela kunokuba phakathi kwe-5% -10%.Izinto eziphathekayo ziya kucutshungulwa, zihlanjwe, zisuswe amanzi, zicudiswe kwaye zidibanise.Ukufuma kwemveliso yokugqibela kunokuba ngaphakathi kwe-2%. |

| Emva kokuthengisa Inkonzo | Iinjineli ziyafumaneka ngaphakathi kofakelo |

- Itanki edadayo, yokuhlamba ingatshintshwa ngokwemfuno yomthengi

- icandelo lomatshini njenge-shredder, i-crusher nayo yongeza ngokwemfuno yomthengi

- Ubungakanani bomgca wokuvasa bunokwandiswa kwaye bufutshane njengoko inkqubo yenkqubo isiqulatho esimdaka njenge-oyile, isanti, i-inki nokunye

- Ngoku, i-wiring dryer okanye i-screw dryer ziyafumaneka, inkqubo yokomisa ikwangokobungqingqwa bemathiriyeli

- Ngokubanzi, up 50 microns, wiring eqhotsiweyo

- Izinto eziluncedo:

- Iqela loyilo lobuchwephesha elinamava angama-30 eminyaka

- Ubungakanani bomgca wokuvasa bunoyilo njengemfuno yomthengi

- Ukusetyenziswa kwizinto ezahlukeneyo

- Ukusebenza okuphezulu kunye nokusebenza okuphezulu

- Yonga umsebenzi wakho kunye neendleko zombane

- Umthamo ophezulu wokucubungula: 500-3500kg / hr

- I-PLC edibeneyo kunye nolawulo olwahlukileyo kumatshini ngamnye

- Iphaneli yesikrini sokuchukumisa, ukusebenza lula, ukubeka iliso kunye nokugcinwa

- Izinto ezikrwada zomatshini: umgangatho ophezulu we-304 wentsimbi, ukuqina kunye nokumelana nebhere, ukuqinisekisa ukuba ixesha elide usebenzisa ubomi

- Qinisekisa ukuba akukho ngcoliseko lwesibini kwiiflakes

- Ubuchule obugqwesileyo obucocekileyo

Izinto eziluncedo koomatshini bokurisayikilisha PURUI:

I-1.Plastiki yokusika ifilimu, ukuhlamba, umatshini wokuhlaziya kunye nemveliso ephezulu kunye nokukwazi ukucoceka okugqwesileyo

2.Umgca opheleleyo wokurisayikilisha weplastiki usetyenziselwa ukutyumza, ukuhlamba, ukukhupha amanzi kunye nokomisa ifilimu yePP/PE, ingxowa elukiweyo yePP

I-3.Isakhiwo esilula, ukusebenza okulula, umthamo omkhulu, ukonga amandla, ukhuseleko

I-4.Ukulawula ngokuzenzekelayo, isakhiwo esidibeneyo, ikhono elihle lokuvelisa, ukukwazi ukucoceka okugqibeleleyo

Umatshini wokurisayikilisha weplastiki luhlobo lwezixhobo ezisetyenziselwa ukusetyenzwa ngokutsha kwenkunkuma yeplastiki kwiigranuli okanye iipeliti ezinokuthi ziphinde zisetyenziswe ekwenzeni iimveliso zeplastiki ezintsha.Umatshini usebenza ngokucofa okanye ukucola inkunkuma yeplastiki ibe ngamaqhekeza amancinci, emva koko uyinyibilikise kwaye uyikhuphe ngokufa ukwenza iipellets okanye iigranules.

Kukho iintlobo ezahlukeneyo zeplastiki zokurisayikilisha kunye noomatshini begranulating abakhoyo, kubandakanywa isikrufu esinye kunye ne-twin-screw extruders.Abanye oomatshini baquka iimpawu ezongezelelweyo ezifana nezikrini zokususa ukungcola kwinkunkuma yeplastiki okanye iinkqubo zokupholisa ukuqinisekisa ukuba iipelisi ziqiniswe ngokufanelekileyo.Umatshini wokuhlamba ibhotile ye-PET, i-PP elukiweyo yeengxowa zomgca wokuhlamba

Oomatshini beplastiki bokurisayikilisha kunye noomatshini bokwenza igranulayitha baqhele ukusetyenziswa kwimizi-mveliso eyenza isixa esikhulu senkunkuma yeplastiki, njengokupakishwa, iimoto kunye nokwakha.Ngokuphinda kusetyenziswe inkunkuma yeplastiki, aba matshini banceda ukunciphisa impembelelo yokusingqongileyo yokulahlwa kweplastiki kunye nokugcina izixhobo ngokusebenzisa izinto ebezinokulahlwa ngenye indlela.

Isixhobo sokurisayikilisha ibhetri yeLithium luhlobo lwezixhobo ezisetyenziselwa ukurisayikilisha nokubuyisela izinto ezixabisekileyo kwiibhetri ze-lithium-ion, eziqhele ukusetyenziswa kwizixhobo zombane ezifana nee-smartphones, iilaptops, kunye nezithuthi zombane.Isixhobo sisebenza ngokuqhekeza iibhetri kwiindawo zazo, njenge-cathode kunye nemathiriyeli ye-anode, isisombululo se-electrolyte, kunye neefoyile zetsimbi, kwaye emva koko zahlula kwaye zihlambulule ezi mathiriyeli ukuze zisetyenziswe kwakhona.

Kukho iintlobo ezahlukeneyo zezixhobo zokuhlaziya ibhetri ye-lithium ezikhoyo, kubandakanywa iinkqubo ze-pyrometallurgical, iinkqubo ze-hydrometallurgical, kunye neenkqubo zoomatshini.Iinkqubo zePyrometallurgical zibandakanya ukusetyenzwa kobushushu obuphezulu beebhetri ukubuyisela iintsimbi ezinje ngobhedu, nickel, kunye necobalt.Iinkqubo ze-Hydrometallurgical zisebenzisa izisombululo zekhemikhali ukunyibilikisa amacandelo ebhetri kunye nokubuyisela iintsimbi, ngelixa iinkqubo zoomatshini zibandakanya ukuqhekeza kunye nokugaya iibhetri ukwahlula izixhobo.

Isixhobo sokurisayikilisha ibhetri yeLithium sibalulekile ekunciphiseni impembelelo yokusingqongileyo yokulahlwa kwebhetri kunye nokugcina izixhobo ngokufumana kwakhona iintsimbi ezixabisekileyo kunye nezinto ezinokuthi ziphinde zisetyenziswe kwiibhetri ezintsha okanye ezinye iimveliso.

Ukongeza kwiinzuzo zokusingqongileyo kunye nokugcinwa kwezibonelelo, izixhobo zokuphinda zisetyenziswe ibhetri ye-lithium nazo zineenzuzo zoqoqosho.Ukufumana kwakhona isinyithi esixabisekileyo kunye nezinto ezivela kwiibhetri ezisetyenzisiweyo kunokunciphisa iindleko zokuvelisa iibhetri ezintsha, kunye nokudala imithombo emitsha yengeniso kwiinkampani ezibandakanyekayo kwinkqubo yokubuyisela kwakhona.

Ngaphaya koko, ukwanda kwemfuno yezithuthi zombane kunye nezinye izixhobo zombane kuqhuba imfuneko yoshishino olusebenzayo noluzinzileyo lokurisayikilisha kweebhetri.Isixhobo sokurisayikilisha ibhetri yeLithium singanceda ukuhlangabezana nale mfuno ngokubonelela ngendlela ethembekileyo nengabiziyo yokufumana kwakhona imathiriyeli exabisekileyo kwiibhetri ezisetyenzisiweyo.

Nangona kunjalo, kubalulekile ukuqaphela ukuba ukwenziwa kwakhona kwebhetri ye-lithium kuseyishishini elitsha noko, kwaye kukho imiceli mngeni ekufuneka yoyiswe malunga nokuphuhlisa iinkqubo zokurisayikilisha ezisebenzayo nezingabizi kakhulu.Ukongeza, ukuphathwa ngokufanelekileyo kunye nokulahlwa kwenkunkuma yebhetri kubalulekile ukuphepha iingozi zendalo kunye nempilo.Ngoko ke, imimiselo efanelekileyo kunye namanyathelo okhuseleko kufuneka abekhona ukuze kuqinisekiswe ukuphathwa ngokufanelekileyo kunye nokuhlaziywa kweebhetri ze-lithium.